Modelling coffee brewing using X-rays

Modelling coffee brewing using X-rays

A roasted and ground coffee matrix is a highly complex porous medium characterized by multiscale features. A typical coffee matrix used for double-shot espresso brew is about 15 ml in volume and consists of millions of coffee particles. These coffee particles are produced by grinding roasted coffee beans, and have an approximately bimodal size distribution. A bimodal distribution often results from a process that involves the breakup of several sources of particles, different growth mechanisms, and large particles in a system.

In the case of ground coffee, the first peak of the distribution profile is always at around 30 ∼ 40 μm, representing the so-called “fines”, i.e., inner walls cellular fragments. The second peak represents the so-called “coarses” and their mean size depends on the grinder, with values ranging between 200 and 100 μm. Completing the picture, the coffee particles are not entirely solid but porous material themselves, characterized by many cell-pockets of dimensions 30 ∼ 60 μm inside the particles. Finally, the cell-walls are also porous at nanoscale level.

When we make our double-shot espresso, as water flows through this complex porous structure, many chemical compounds including, among many others, caffeine, trigonelline, polyphenols and polysaccharides, are diffused and convected out of the solid matrix to finally enter into the cup and determine the quality (understood as flavour and mouthfeel) of the final beverage. This coffee extraction process is especially difficult to model. This is not simply because of the complex topological features related to the multiscale nature of coffee bed geometry as explained above, there are also many other physical processes concomitant to the simple diffusion and convection.

For example, the porous medium undergoes geometric changes due to migrations, erosions, and swelling of the particles; solubilization of many hydrophilic substances is also present, as are the emulsification of insoluble coffee oils, the suspension of solid coffee cell-wall fragments, and carbon dioxide degassing and supersaturation. These physical processes are all interconnected, rendering the modelling of coffee extraction very challenging.

In order to predict the coffee quality and propose better brewing protocol a priori, many works have tried to model the extraction process using a variety of simulation techniques. However, in most of the aforementioned modelling and simulations, the fluid dynamics through the coffee matrix was either characterized by average porosity and permeability or was resolved by flows through artificial packing of many spheres/disks. These simulations may not be able to capture some important features of coffee extraction.

Quality coffee brewing

As any coffee aficionado knows, particle size distribution is quite influential to the final quality of the brew. It follows that it is paramount to accurately model the whole spectrum of particle size in coffee extraction simulation. One way to achieve this is a straightforward high-resolution mapping—capturing all the microscopic details of a coffee matrix— by using X-ray microtomography (microCT)/X-ray microscopy (XRM) to scan the coffee matrix, and build a porous medium model using the 3D-reconstructured inner topology. This way, not only the full particle size distribution is considered, but the spatial permeability fluctuation in the matrix as well. The spatial permeability fluctuation could correlate to the “partially clogged” phenomenon, which may cause very fine coffee powder to have less extraction rate.

With X-ray microCT, it is also possible to scan both the pre-extraction (dry) coffee matrix and the post-extraction (wet) one. The comparison could reveal some information about how the porous structure changes during the extraction process. This information could provide important guidance to model different physical processes that lead to geometric change and matrix restructuring during extraction. But nobody had done this in order to directly simulate coffee extraction simulation.

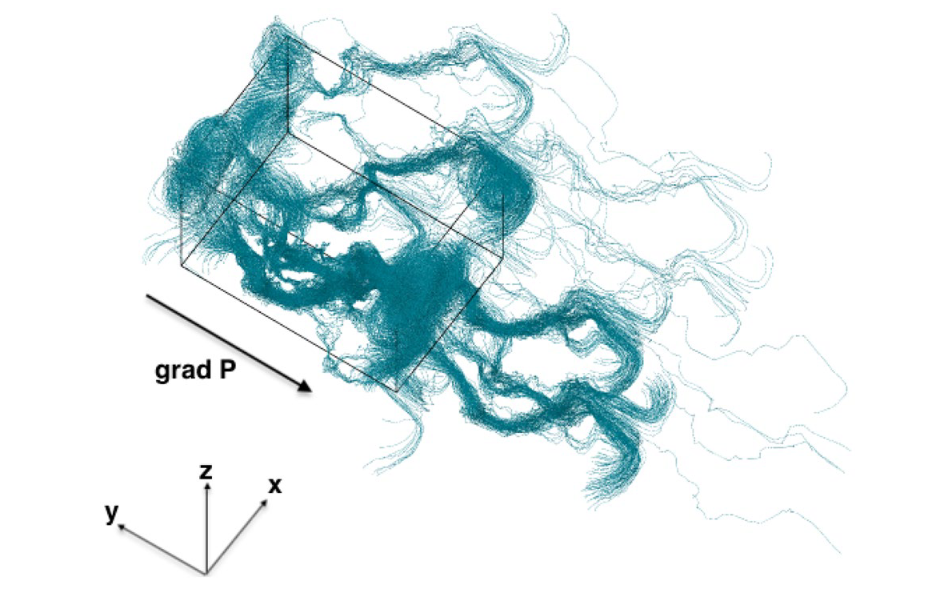

Now, a team of researchers uses microCT reconstructured data 1 to build a static porous medium model, and simulate the percolation process using the smoothed particle hydrodynamics method (SPH).

The researchers determine the simulated medium permeability at different pressure gradient and compare them to experimental data in literature. They are able to show that inertial effects are quite influential at the pressure gradients typically considered in espresso brewing. Actually, the inconsistency of many results of coffee matrix permeability found in literature can be explained by the above-mentioned inertial effect.

The team also examined several types of coffee powder, and their permeability and tortuosity are measured systematically using SPH simulation. This allows to establish a link between coffee powder granulometry and other microstructural features with extraction efficiency.

By comparing the microCT images of pre- and post-extraction coffee matrices, it is found that a decreasing porosity profile (from the bottom-outlet to the top-inlet) always develops after extraction. This counterintuitive phenomenon can be explained using a pressure-dependent erosion model.

These results reveal not only some important hydrodynamic mechanisms of coffee extraction, but also show that microCT scan can provide useful microscopic details for coffee extraction modelling. MicroCT scan establishes the basis for a data-driven numerical framework to explore the link between coffee powder microstructure and extraction dynamics, which is the prerequisite to study the time evolution of both volatile and non-volatile organic compounds and then the flavour profile of coffee brews.

Author: César Tomé López is a science writer and the editor of Mapping Ignorance

Disclaimer: Parts of this article might have been copied verbatim or almost verbatim from the referenced paper.

References

- Chaojie Mo, Richard Johnston, Luciano Navarini, Furio Suggi Liverani & Marco Ellero (2024) Exploring the link between coffee matrix microstructure and flow properties using combined X‑ray microtomography and smoothed particle hydrodynamics simulations Scientific Reports doi: 10.1038/s41598-023-42380-y ↩