Making truly multifunctional cellulose hybrid materials

When we think about the new materials of the future some names may come to mind: pure carbon, in the form of graphene or nanotubes or buckyballs or any other exotic allotrope; or some kind of oxide of these carbon allotropes; or some strange combination of metal oxides, manufactured via processes that remind us of science fiction, with ultra vacuums or temperatures extremely close to absolute zero. But the range of new materials is not necessarily limited to products strange to ordinary human life. The main component of paper or cotton, cellulose, could be a raw product with very interesting properties with just minor modifications. And CO2 neutral.

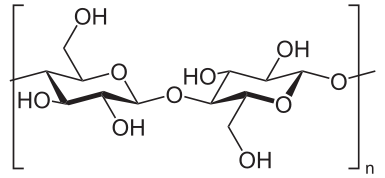

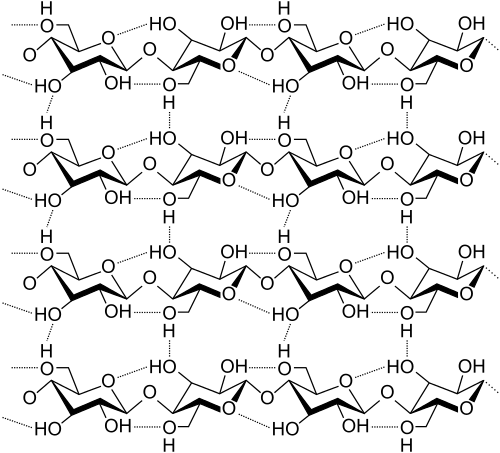

Cellulose is a polysaccharide composed by a linear chain of D-glucose units. Cellulose chains organize into a hierarchical structure of fibers, microfibrillated fibers and microfibrils. Due to this structure cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. As a consequence cellulose is the most abundant biopolymer on Earth, and virtually an unlimited resource, that is why it is so appealing to use it as a base for new technologies and applications: from the classical fiber based reinforcements and advanced water filtration, which started their development some sixty years ago, to the just-starting new ways of storing energy or printing electronics.

Another possibility is to modify cellulose so that it may adquire new functionalities. One way to achieve this is to introduce homogeneously another substance into the structure. Now, a group of researchers from CIC nanoGUNE, CFM and DIPC, including DIPC associate Celia Rogero, has performed1 the first infiltration study of cellulose and the first study using single substances (precursors). This work, published in Chemistry of Materials, may open the possibility of making truly multifunctional cellulose hybrid materials.

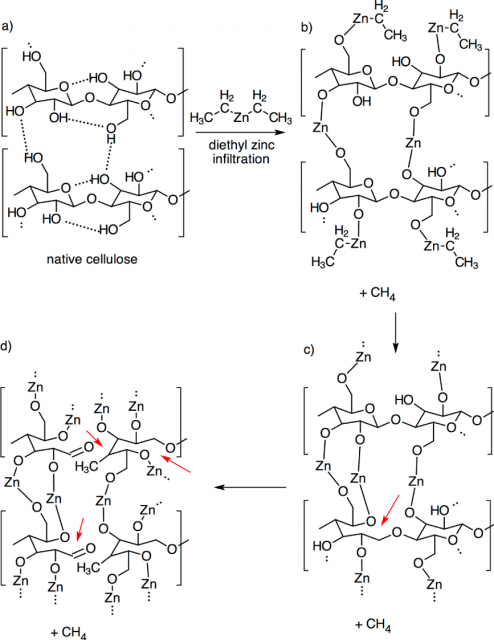

The technique that these scientists have employed is called vapor-phase infiltration. It allows the vaporized precursors, supplied sequentialy in a solvent free environment, to diffuse beyond the surface of cellulose and into the core of the structure, where they can react with active sites.

The first use of the technique was done on spider silk, resulting in significant changes in the mechanical properties due to chemically induced changes in the protein and cross-linking of the proteins with metal ions. It was also used with egg collagen with similar results. Till now vapor-phase interactions with cellulose were done only at the surface level and using cellulose replicas (TiO2) or composite TiO2/cellulose structures.

All this experiments used precursors presented in pairs, i.e., an active substance and a solvent. For the first infiltration study of cellulose the strategy was that single precursors would specifically target and consume the -OH bonds that naturally create the so-called water bridges that cement the hierarchical structure of cellulose. The tests were done using trimethyl aluminium (TMA) or diethyl zinc (DEZ) as precursors.

The mechanical properties of the new hybrid celluloses were measured and shown to be dependent not only on the total amount of precursor that the cellulose has been exposed to but also on which precursor is used for the process, introducing a certain level of tunability. Thus, for cellulose infiltrated with diethyl zinc, the ultimate tensile strength was seen to nearly double from ∼160 to ∼260 MPa. A significant increase was also seen in the elastic modulus, with values increasing from ∼1.8 to ∼4.5 GPa. In contrast, cellulose infiltrated with trimethyl aluminum showed very little improvement in mechanical properties.

Therefore, choosing the right precursors or mix of precursors it could be possible to introduce new functionalities with improved mechanical behaviour. For example, if a hybrid cellulose could be made to be stronger, hydrophobic and electrically conductive, it would represent a serious step towards new applications. While maintaining the CO2 neutrality.

Author: César Tomé López is a science writer and the editor of Mapping Ignorance.

References

- Gregorczyk K.E., Miren Garcia Sanz, Itxasne Azpitarte Irakulis, Celia Rogero & Mato Knez (2015). Tuning the Tensile Strength of Cellulose through Vapor-Phase Metalation, Chemistry of Materials, 27 (1) 181-188. DOI: http://dx.doi.org/10.1021/cm503724c ↩

1 comment

[…] La celulosa es el biopolímero más abundante, presente en las plantas verdes. El algodón, por ejemplo, está compuesto en un 90% por celulosa, y con las fibras de celulosa se fabrica el papel. No parece que sea un material […]