Is thermal sterilisation of preservative-free rice cakes possible?

High-moisture soft solid snack foods such as rice cakes have become increasingly popular. Most of these snacks are freshly made and sold on the spot, whilst industrially produced versions use chemical preservatives to inhibit microbial growth and improve shelf life. With the increasing demand for preservative-free foods from some consumers, physical methods are needed to replace the chemicals. But these methods have their limitations.

A team of researchers from the University of Queensland (Australia) and Mauricio Rincón Bonilla (BCAM) has explored 1 the limits of thermal treatments for preventing bacterial spoilage when chemical preservatives are not present. Steamed rice cakes, which are traditional high-moisture snacks in many Asian countries, are used as a case study.

Steamed rice cakes have a moisture content of 35%–50% depending on the formulation. They spoil after only 2–3 days due to the growth of microorganisms such as Bacillus spp., Staphylococcus aureus, and Staphylococcus epidermidis. Heat-resistant spore-forming microorganisms can survive the steam cooking process, which includes Bacillus cereus, a common toxigenic food poisoning bacterium. B. cereus spores in food products may survive when cooked at or below 100 °C and following cooling may germinate and grow to dangerous levels in the absence of competing bacteria. Hence, in order to investigate the efficiency of thermal sterilisation B. cereus spores are an excellent control variable.

Thermal sterilisation for edible products is an old technology. It was Louis Pasteur who first introduced it for wine in 1863. Pasteurisation of milk and beer are, today, examples of established technologies, where thermal modelling is mostly aimed at optimising temperature profiles in existing devices.

Most reports on thermal modelling in cans and pouches have focused on determining the temperature profile and thermal properties. While these temperature profiles are sometimes used to predict microbiological inactivation or the evolution of quality variables, the lethality of the process is usually not validated by independent microbial methods which will give more precise information about sterilisation than the values calculated from temperature measurements.

The researchers assessed the preservative-free microbial safety of thermal processing of steamed rice cakes through a combination of experiment and modelling, something that has not been previously reported for these high-moisture soft-solid foods.

Experiments started cooking rice cakes. Ingredients were sticky rice flour, rice flour, sugar and tap water. They mixed were mixed in a ratio of 3:2:1:3.6 in a bench mixer at low speed for 1 min to produce a dough which was then formed into small rice balls weighing 50 g. The rice balls were cooked in a steamer for 15 min. Once removed from the steamer and cooled down to room temperature, each rice cake was packaged in single-layer food wrap.

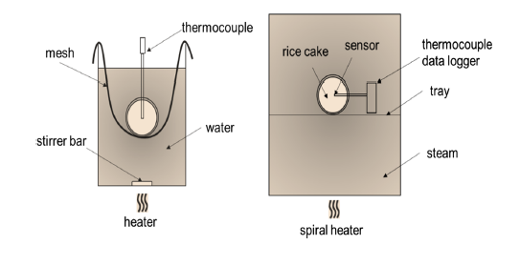

Then, the thermal properties of steamed rice cakes were extracted from fitting temperature profiles of samples in both a water bath and an autoclave, the latter system covering a wider range of temperatures (Figure 1). The thermal inactivation kinetic parameters of B. cereus spores in steamed rice cakes was measured in an oil bath set at various temperatures.

The multiphysics model assumed some things. First, the steamed rice cake is supposed to be a sphere of constant radius R, independently of the actual shape or whether there may be some swelling during the sterilisation process. Second, only conductive and convective heat transfers are considered, no thermal radiation is included. Third, the wrapping influence is negligible.

Finally, the combination of thermal inactivation kinetics and modelling based on the thermal properties was used to assess the effect of processing conditions and product dimensions on rice cake sterilisation. The researchers found that increasing the heat transfer coefficient (via flow dynamics) and processing temperature can be used to improve inactivation. But there is a major limiting factor: conduction within the rice cake is governed by its low thermal conductivity.

One solution is decreasing the diameter of the rice cakes, which increases the rate of inactivation. Another possibility is altering their shape into disks and cylinders to decrease the distance between the surface and the centre. A third one could be the use of fillings with a better thermal conductivity, something that should be investigated further.

In any case, the model and approach developed can also be expected to be useful for optimising sterilisation processes and devices for other high-moisture food systems.

Author: César Tomé López is a science writer and the editor of Mapping Ignorance.

References

- Jing Ai, Torsten Witt, Michael J. Gidley, Mark S. Turner, Jason R. Stokes, Mauricio R. Bonilla (2018) Modelling of Thermal Sterilisation of High-Moisture Snack Foods: Feasibility Analysis and Optimization Food and Bioprocess Technology doi: 10.1007/s11947-018-2075-8 ↩