Fully recyclable materials for food packaging

Author: Ainara Sangroniz is a researcher at POLYMAT, Department of Polymer Science and Technology, UPV/EHU

Packaging is essential to preserve the food quality and safety and to extend the shelf life of the stored product reducing the food waste. In this sector, plastics are the material of choice because they are cheap, lightweight and easy to process. The main requirement for packaging materials is to maintain the food in good environmental conditions and therefore adequate barrier character to gases and vapours is required. Depending on the stored product different permeability properties are necessary, for example for bakery products the uptake of water must be avoided whereas for meat an adequate permeability to oxygen is necessary.

The most widely employed materials in food packaging applications are polyolefins such as poly(ethylene) and poly(ethylene terephthalate) due to their excellent performance and low price. However, once they are disposed of their non-biodegradable character together with the lack of effective recycling systems is contributing to their accumulation in our ocean and landfills.

During more than a decade, biodegradable polymers have been envisioned as an alternative to solve problems arising from plastic accumulation as these polymers under adequate conditions could be degraded to carbon dioxide, water, biomass, etc in a reasonable period of time. Among biodegradable polymers poly(lactide) and poly(hydroxybutyrate) have attracted a lot of attention but their poor mechanical properties, they show a brittle behaviour, together with the high permeability, in the case of poly(lactide), has limited to some extent their implementation in the packaging sector.

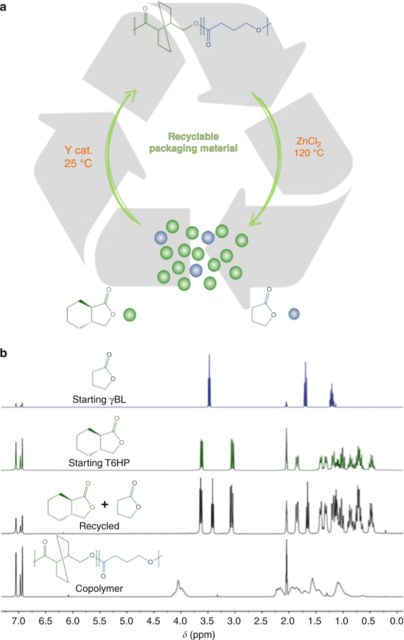

In the last decade, chemically recyclable polymers have emerged as a promising solution to solve the problem of plastic waste. This kind of materials, once they have reached the end of their life, can be fully depolymerized back to their original monomers employing mild conditions in an economic and environmentally sustainable manner. Thus, these monomers can be recovered to synthesize new material and potentially no plastic waste would be generated. Among the chemically recyclable materials that have been recently reported, those based on -butyrolactone core are very interesting since they are obtained from renewable resources and they can be fully depolymerized back to the original monomers in a cost-effective manner.

We have studied 1 the potential application of plastics based on -butyrolactone core for packaging applications. We have found that poly(-butyrolactone) shows an outstanding mechanical performance but a high permeability to gases and vapours, which make it unsuitable for packaging applications. On the other hand poly(trans-hexahydrophthalide) shows just the opposite behaviour: a low ductility and low permeability, i.e. the mechanical properties are not adequate but it has a very good barrier character.

Notably, when these polymers are combined, it has been found that the copolymers present a good mechanical performance and adequate barrier properties to water vapour and oxygen, that are much better than biodegradable polymers such as poly(lactide) and similar to the polymers used nowadays in the market such as poly(ethylene) and poly(ethylene terephthalate). Furthermore, the chemical recyclability of these copolymers has been studied observing that they are fully chemically recyclable obtaining the original building blocks.

This work represents a step forward in packaging materials but there are still some unanswered questions such as the biodegradation and composting of these materials. Furthermore, the economical aspect and the life-cycle assessment to evaluate the environmental impact of the product´s life have to be also considered. Still, further efforts are needed to develop materials with desired properties that are fully recyclable employing efficient and green processes and that would lead to establishing a circular economy approach towards sustainability.

References

- Ainara Sangroniz, Jian-Bo Zhu, Xiaoyan Tang, Agustin Etxeberria, Eugene Y.-X. Chen, Haritz Sardon (2019) Packaging Materials with Desired Mechanical and Barrier Properties and Full Chemical Recyclability Nature Communications doi: 10.1038/s41467-019-11525-x. ↩