Bubble wrap and non-destructive testing

Bubble wrap and non-destructive testing

Non-destructive testing allows engineers to evaluate the integrity of structures such as pipelines, tanks, bridges, and machinery without dismantling them. Conventional approaches rely on loudspeakers, lasers, or electric sparks. While effective, these systems can be difficult or dangerous to use in flammable or confined areas and require considerable power to function effectively.

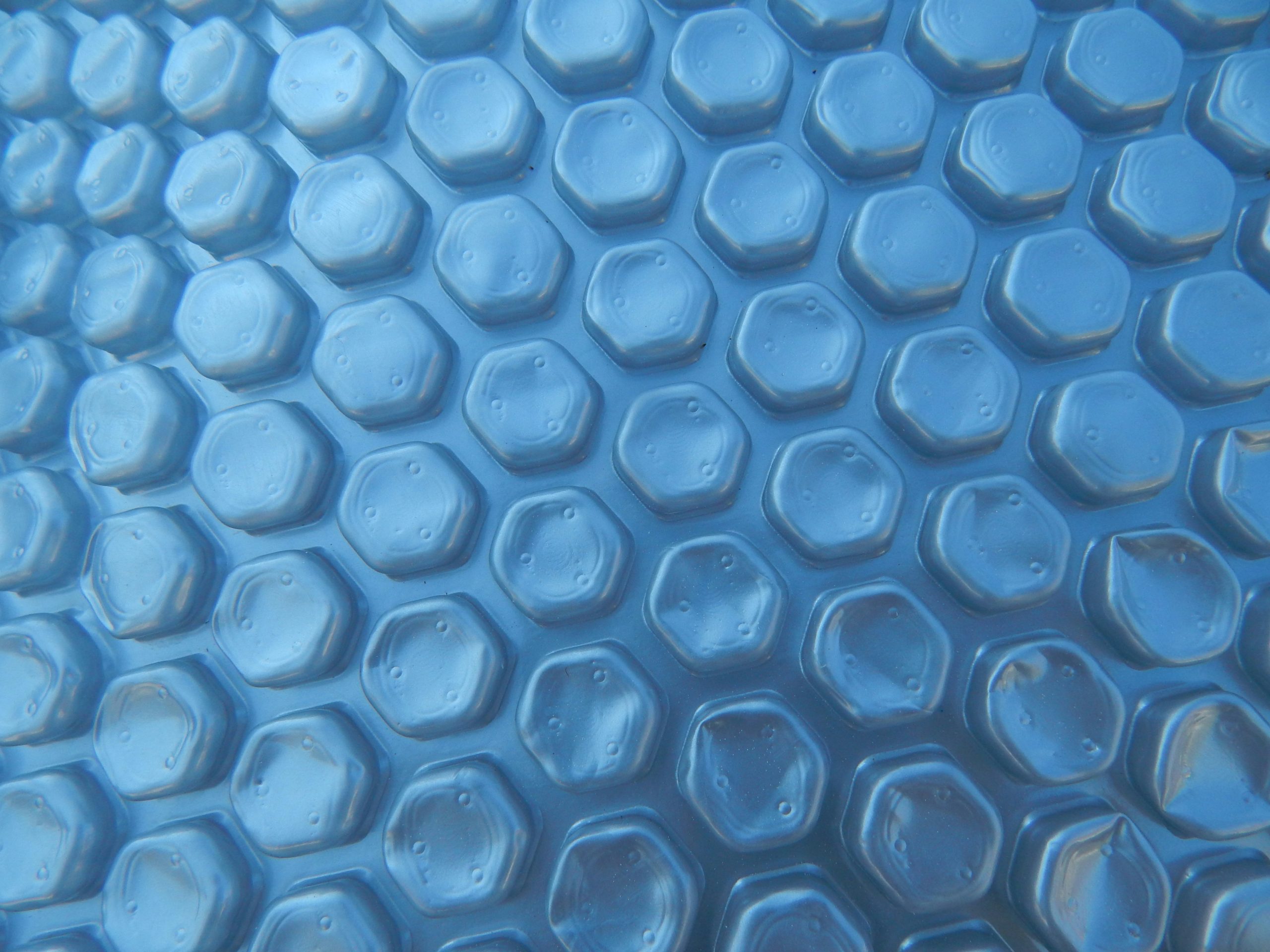

Now, a new study 1 shows how a common packaging material can replace power-hungry devices in non-destructive testing. The team found a simple way to test pipes for hidden flaws by using bubble wrap.

The researchers discovered that the sharp crack of a bubble burst can be a viable substitute for the expensive, energy-dependent tools usually employed in non-destructive testing. The researchers claim the method can detect objects inside a pipe within a 2% error margin, without requiring electricity or heavy equipment.

The team tested several types of bubble wrap and measured their acoustic characteristics, including peak sound pressure, pulse width, and frequency range. To their surprise, the bursts produced frequencies of up to 40 kilohertz, sufficient for precise acoustic testing. The team then built a system using bubble wrap as the sound source, a microphone for signal collection, and a computer running wavelet-based sound analysis to track how sound waves reflected inside a pipe.

Compared with traditional impulse sources such as loudspeakers, firecrackers, or laser-induced plasma, the bubble-wrap system eliminates complex wiring and potential hazards. It can also be safely used in flammable environments where electrical devices might pose a risk. By analysing how the echoes changed when a foreign object was present, the researchers were able to identify the object’s position with a high degree of accuracy.

Only a sheet of bubble wrap

With only a sheet of bubble wrap and a microphone, the team could identify small variations in reflected sound that revealed the position of internal obstructions. The accuracy of these measurements was comparable to results obtained using far more complex devices.

The technique’s flexibility also allows it to be adapted to different situations. Changing bubble size or internal pressure shifts the sound frequency, enabling the method to be applied to various pipe diameters and materials. The simplicity of the setup means that one operator can perform inspections with minimal training.

What began as a moment of curiosity, an observation made while casually popping bubble wrap, became a practical acoustic measurement tool. The study demonstrates how familiar materials can yield precise scientific applications when examined systematically. The group plans to further test the system under varying temperature and pressure conditions and to explore ways to develop a compact, handheld version suitable for field inspections. Continued refinement may improve sensitivity, allowing the detection of deeper or more complex structures.

References

- Shuichi Yahagi et al (2025) Electric-power free impulse point sound source generation system with bubble wrap bursting phenomena for simplified non-destructive testing Measurement doi: 10.1016/j.measurement.2025.119192 ↩