Growing hamburgers on a petri dish

The other day I came across an article about the revolution of cultured meat at El País Semanal, although that was not the first time I read about this. Still, I have to admit is such a shocking subject that I thought it may deserve a post explaining how advanced this technology is at the moment. It was back in August 2013 when meat engineering went mainstream, after the first-ever livestock-free hamburger was cooked and tasted live in London. The hamburger had a staggering total cost of 250000€, giving the idea of how early in development this product still is. Nobody should be expecting to buy a cultured hamburger anytime soon.

The reasons why meat engineering has become a field of research are essentially three. First, the predicted increase in meat demand as a consequence of the growth in population. Second, the apparently growing concern linked to the environmental impact of breeding livestock. It is estimated that livestock is responsible for approximately 15% of the total greenhouse gas emissions 1. Finally, the growing society concerns about animal welfare and health issues.

Growing in vitro meat is a concept that started roughly a decade ago, when the government from The Netherlands decided to fund a project aiming to produce cultured meat. This funding effort comprised four years starting in 2005. It was on 2012 when Professor Mark J. Post from Maastricht University seems to formally “cut the ribbon” after publishing a review paper called “Cultured meat from stem cells: Challenges and prospects” 2. The abstract mentions the following statement:

“The generation of bio-artificial muscles from satellite cells has been ongoing for about 15 years, but has never been used for generation of meat, while it already is a great source of animal protein”.

The methodology relies on advances made by regenerative medicine pursuing the reconstruction of deteriorated muscle tissue from individuals, but using their own cells. When extrapolated into livestock-free meat production, muscle-specific stem cells or satellite cells are collected from a small bovine muscle biopsy. Those are multipotent cells lacking cytoplasm and found in mature muscle with the ability to differentiate into skeletal muscle cells themselves. After collection, cells undergo an expansion stage in which the number of cells is increased exponentially. Subsequently, cells are differentiated into skeletal muscle cells (forming fibres) and assembled into the actual meat product, ready to cook. However, as easy as this process seems, it faces a bunch of hurdles some of which I would like to explain here in more detail.

As the satellite cell expansion stage requires cell culturing medium (like any other cell growing in isolation), this is where an important obstacle is met. Cells need serum to provide the essential growth factors allowing them to proliferate (even though its composition is not entirely known), but serum is obtained from bovine foetuses’ blood, making necessary to produce culture media containing a mixture of animal-free components resembling the properties of serum in an industrial scale. Furthermore, the composition of this medium must be safe for humans meaning a lot of testing would have to be done before it can be even considered a viable commercial product.

A second challenge to overcome relies in the fact that muscle cells need tensional forces to fully differentiate. This tension contributes to initiate expression of contractile proteins such as myosin and actin (forming striations), which are essential for their physiological role. This key feature means cells must be cultured in biomaterials such as hydrogels which currently are made out of denatured bovine collagen. This structure allows the cells to adopt a tissue-like configuration (resembling muscle fibres) and be anchored, thus producing the necessary tension to fully differentiate. A synthetic substitute has to be designed and tested both ensuring safety and scalability to allow industrial applications.

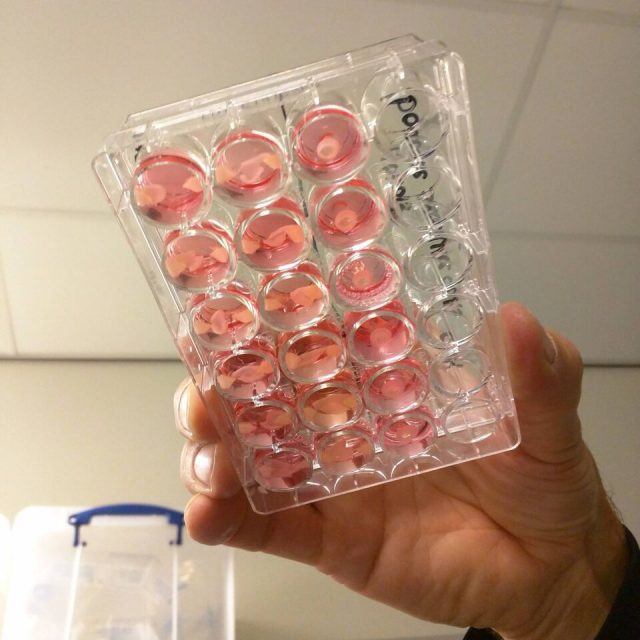

Perhaps the biggest difficulty may be to find a way to produce artificial meat in large scale. To successfully produce the edible hamburger back on 2013, two dimensional cell cultures were grown in multilayer cell culture chamber flasks, requiring large facilities and infrastructure to produce the 20000 muscle strands needed to produce the hamburger. Cells would need to proliferate in three dimensional large bioreactors while somehow providing a scaffold allowing them to differentiate. A possibility could be to have clusters of cells intercalated within layers of an intricate network with a structure similar to that of a spider web. This would allow to increase the amount of cells per surface unit.

Yet another drawback relies on the fact that real meat is not just made out of muscle cells, but also contains adipose cells, vessels or myoglobin which altogether give the characteristic meaty taste. Hence, a way to grow co-cultures of different types of cells may be a requisite to get a product that consumers will find appealing. Actually, this latter point is likely the most unforeseeable one, because the potential customers of such product will have to deal with not just the taste of the synthetic meat but also the psychological element associated to it. Will people agree to buy and eat meat whose origin is not an actual animal? The average citizen does not have a deep knowledge about stem cells technology, so there is a chance there is a rejection as it currently happens with genetically modified organisms. In addition, authorities will have to assess the lack of any potential harm to humans by independent bodies as well as create a regulatory framework to ensure hygiene and safety is guaranteed throughout the manufacturing process.

In summary, synthetic meat engineering seems to be yet another unexpected application from regenerative medicine which, although many years away from being a reality opens up the possibility of dealing with a number of concerns like the ever-growing population and their associated feeding needs and animal welfare.

References

- Post MJ. An alternative animal protein source: cultured beef. Ann. N Y Acad Sci. 2014 Nov; 1328:29-33. doi: 10.1111/nyas.12569. ↩

- Post MJ. Cultured meat from stem cells: challenges and prospects. Meat Sci. 2012 Nov;92(3):297-301. doi: 10.1016/j.meatsci.2012.04.008. Review. ↩