Injectable hydrogels for biomedical uses

Gel-like materials that can be injected into the body hold great potential to heal injured tissues or manufacture entirely new tissues. Many researchers are working to develop these hydrogels for biomedical uses, but so far very few have made it into the clinic.

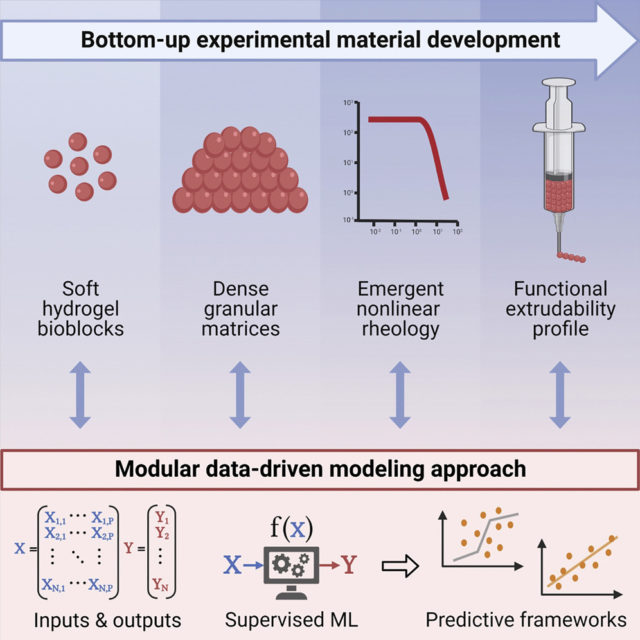

To help guide in the development of such materials, which are made from microscale building blocks akin to squishy LEGOs, a team of researchers has now created 1 a set of computational models to predict the material’s structure, mechanical properties, and functional performance outcomes. The researchers hope that their new framework could make it easier to design materials that can be injected for different types of applications, which until now has been mainly a trial-and-error process.

Hydrogels modelling

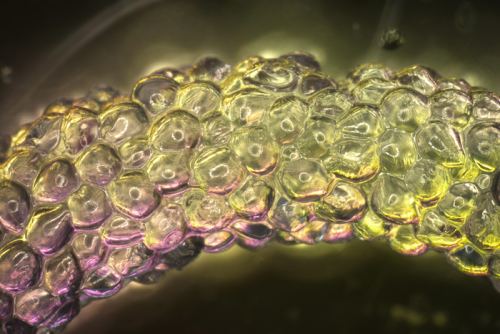

When individual hydrogel blocks are densely compacted together, they form a gel-like material known as a granular matrix. These materials can act as a solid or a liquid, depending on the conditions, which makes them good candidates for applications such as 3D-bioprinting engineered tissues. Once injected or implanted into the body, they could release drugs or help to regenerate injured tissue.

Figuring out how to get these materials to be reliably injectable turned out to be a difficult task that required a lot of trial-and-error experimentation, by changing different features of the gels in hopes of optimizing their structure and mechanical behaviour for injectability. To create their design framework, the researchers broke the assembly process down into several stages. They modelled each of these stages separately, using data from their own experiments, which were done under a variety of different conditions.

In the first stage, the model analysed how bioblock properties are affected by the starting material of the blocks and how they are assembled. In the second stage, the bioblocks are packed together to form structures called “granular hydrogels.” Through their modelling, the researchers identified several factors that influence the injectability of the final gel, including the size and stiffness of the bioblocks, the viscosity of the interstitial fluid between the blocks, and the dimensions of the needle and syringe used to inject the gel.

Better injectability

Now that the process has been modelled from start to finish, the researchers can use their model to predict the best way to create a material with the traits they need for a particular application, instead of going through an extensive trial-and-error process for each new material. Using this modelling approach, one can try to develop materials that could be used for medical applications such as repairing heart defects or delivering drugs to the gastrointestinal tract.

The researchers have also made their models and the data they used to generate them available online for other labs to use.

References

- Connor A. Verheyen, Sebastien G.M. Uzel, Armand Kurum, Ellen T. Roche, Jennifer A. Lewis (2023) Integrated data-driven modeling and experimental optimization of granular hydrogel matrices Matter doi: 10.1016/j.matt.2023.01.011 ↩