Chemically tailoring layered 2D MXenes

A new process that lets scientists chemically cut apart and stitch together nanoscopic layers of two-dimensional materials — like a tailor altering a suit — could be just the tool for designing the technology of a sustainable energy future. Researchers have developed a method for structurally splitting, editing and reconstituting layered materials, called MAX phases and MXenes, with the potential of producing new materials with very unusual compositions and exceptional properties.

A “chemical scissor” is a chemical designed to react with a specific compound to break a chemical bond. The original set of chemical scissors, designed to break carbon-hydrogen bonds in organic molecules, was reported more than a decade ago. In a paper recently published in Science 1, the international team reported on a method to sharpen the scissors so that they can cut through extremely strong and stable layered nanomaterials in a way that breaks atomic bonds within a single atomic plane, then substitutes new elements — fundamentally altering the material’s composition in a single chemical “snip.”

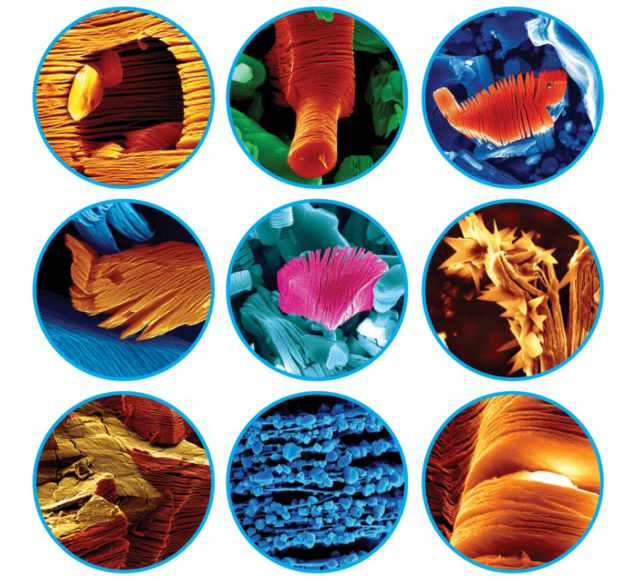

The team has been studying the properties of a family of layered nanomaterials called MXenes, that they discovered in 2011. MXenes begin as a precursor material called a MAX phase; “MAX” is a chemical portmanteau signifying the three layers of the material: M, A, and X. Applying a strong acid to the MAX phase chemically etches away the A layer, creating a more porously layered material — with an A-less moniker: MXene.

The discovery came on the heels of worldwide excitement about a two-dimensional nanomaterial called graphene, posited to be the strongest material in existence when the team of researchers who discovered it won the Nobel prize in 2010. Graphene’s discovery expanded the search for other atomically thin materials with extraordinary properties — like MXenes.

The team has been assiduously exploring the properties of MXene materials, leading to discoveries about its exceptional electrical conductivity, durability and ability to attract and filter chemical compounds, among others. But in some ways, the potential for MXenes has been capped from their inception by the way they’re produced and the limited set of MAX phases and etchants that can be used to create them.

Previously new MXenes only could be produced by adjusting the chemistry of the MAX phase or the acid used to etch it. While this allowed to create dozens of MXenes, and predict that many dozen more could be created, the process did not allow for a great deal of control or precision. By contrast, the new process is a “chemical scissor-mediated structural editing of layered transition metal carbides,” more like performing surgery.

The first step is using a Lewis acidic molten salt (LAMS) etching protocol that removes the A layer, as usual, but is also able to replace it with another element, such as chlorine. This is significant because it puts the material in a chemical state such that its layers can be sliced apart using a second set of chemical scissors, composed of a metal, such as zinc. These layers are the raw materials of MAX phases, which means the addition of a bit of chemical “mortar” — a process called intercalation — lets the team build their own MAX phases, which can then be used to create new MXenes, tailored to enhance specific properties.

In addition to building new MAX phases, the team also reported on using the method to create MXenes that can host new “guest atoms” that it previously would not have been chemically able to accommodate — further expanding the family of MXene materials.

The next step for this research, according to the authors, is the delamination of two- and three-dimensional layered carbides, as well as metal intercalated two-dimensional carbides, into single- and few-layer nanosheets. This will allow the researchers to characterize their fundamental properties to optimize the new materials for use in energy storage, electronics and other applications.

This research opens a new era of materials science, enabling atomistic engineering of two-dimensional and layered materials. It shows a way to assemble and disassemble these materials like LEGO blocks, which will lead to the development of exciting new materials that have not even been predicted to be able to exist until now.

References

- Haoming Ding et al (2023) Chemical scissor–mediated structural editing of layered transition metal carbides Science doi: 10.1126/science.add5901 ↩