Unveiling the thermal secrets of tricalcium aluminate

Unveiling the thermal secrets of tricalcium aluminate

Cement is a fundamental material in modern construction, used in everything from buildings to bridges. One of its key components, tricalcium aluminate (C₃A), plays a crucial role in determining cement’s setting time and durability. A recent study 1 has provided new insights into how C₃A behaves under heat, combining computer simulations with experimental data to deepen our understanding of its thermal properties.

But beyond its role in cement, the research suggests that C₃A may have an exciting new application: thermal energy storage. This discovery could open the door for its use in thermal batteries, a technology that could help store heat for later use, improving energy efficiency in various industries.

What is tricalcium aluminate and why does it matter?

Tricalcium Aluminate (Ca3Al2O6 or, for short, C3A) is a major component in Portland cement, the most widely used cement type. It reacts quickly with water during the cement-setting process, influencing the material’s early strength and durability. However, despite its importance, its thermal properties have not been fully understood—until now.

This study aimed to fill that gap by investigating how C₃A behaves under heat and whether it can efficiently store and release thermal energy. The researchers used a two-part approach:

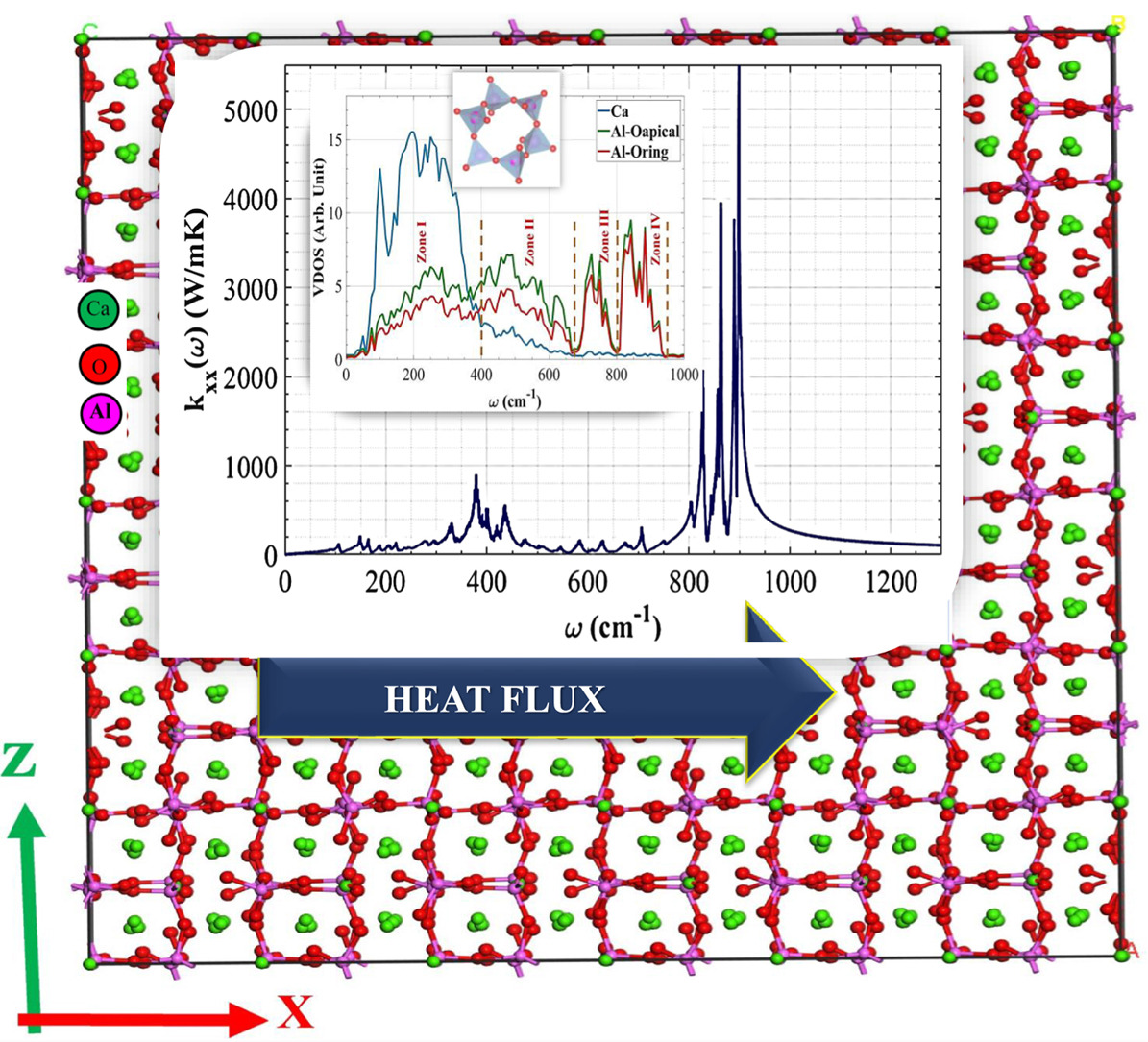

- Molecular Dynamics Simulations – These computer simulations modelled how C₃A’s atoms move and interact under different temperatures, revealing key thermal properties at the microscopic level.

- Experimental Validation – Laboratory tests were conducted to confirm the accuracy of the simulations and measure properties like thermal expansion, heat capacity, and thermal conductivity.

How tricalcium aluminate reacts to heat

The study revealed several important properties of C₃A that could impact its use in both construction and energy storage. First, like most materials, C₃A expands when heated. Understanding this expansion helps engineers predict how cement structures will respond to temperature changes, reducing the risk of cracking and structural damage.

Heat capacity determines how much heat a material can absorb before its temperature rises. The study found that C₃A has a relatively high heat capacity, meaning it can absorb and store significant amounts of thermal energy. This makes it a promising candidate for thermal battery applications (more on this later).

Finally, thermal conductivity measures how well a material transfers heat. The study found that C₃A conducts heat at a moderate rate, meaning it can hold heat without losing it too quickly—another promising sign for thermal storage applications.

Potential use of tricalcium aluminate as a thermal battery

One of the most exciting takeaways from this research is the possibility of using C₃A as a thermal battery. A thermal battery stores heat instead of electrical energy. It works by absorbing heat when energy is available (e.g., from solar panels or industrial waste heat) and releasing it later when needed (e.g., for heating buildings or generating electricity). Thermal batteries are particularly useful in renewable energy systems and industrial processes where waste heat can be recycled.

C₃A can absorb and retain large amounts of heat, making it effective for storing thermal energy. Furthermore, it transfers heat at a controlled rate, preventing excessive heat loss. But, importantly, unlike rare materials used in other batteries, C₃A is already mass-produced in cement manufacturing, making it affordable and widely available.

The potential applications of a C₃A-based thermal battery include renewable energy storage, where excess heat from solar power plants can be stored and used at night; industrial waste heat recovery, as factories and power plants generate massive amounts of waste heat, which could be stored and reused for heating or electricity generation; and more efficient heating systems, because C₃A-based materials could improve the efficiency of district heating systems, where heat is distributed to multiple buildings from a central source.

Implications for the construction industry

By understanding how C₃A behaves under heat, cement manufacturers can optimize production processes to improve energy efficiency and durability, resulting in a smarter cement production

Since C₃A expands with heat, engineers can use this data to prevent cracks and damage in concrete structures exposed to extreme temperatures, with more durable infrastructure as a result.

A material with dual benefits

This study has revealed not only how C₃A behaves under heat but also its potential beyond cement. With its ability to store and release heat efficiently, C₃A could become a key player in the emerging field of thermal energy storage.

By bridging the gap between construction materials and energy storage technologies, this research paves the way for more durable infrastructure and a greener energy future. As scientists and engineers continue to explore these possibilities, C₃A might soon be just as valuable for storing energy as it is for building our world.

Author: César Tomé López is a science writer and the editor of Mapping Ignorance

Disclaimer: Parts of this article may have been copied verbatim or almost verbatim from the referenced research paper/s.

References

- Prodip Kumar Sarkar, Guido Goracci, Jorge S. Dolado (2025) Thermal properties of tricalcium aluminate: Molecular dynamics simulation and experimental approach Cement and Concrete Research doi: 10.1016/j.cemconres.2024.107780 ↩