Are we really prepared for bioplastics?

You have probably heard of the plastic island, an enormous area full of plastic garbage, gathered by oceanic currents, in the North Pacific Ocean. In the last few decades the amount of plastic debris in this area has increased two orders of magnitude, representing one of the best examples of the environmental impact caused by polymeric materials1. In a very interesting documentary released in 2009, Plastic Planet, viewers were made aware of the damage caused both to the environment and our health by the omnipresence of plastic materials in our daily lives.

Petroleum-based polymeric materials have become a commodity: they are used in an ever increasing range of applications and in a very large volume, causing a remarkable impact in terms of landfill volume, CO2 emissions and non-renewable resources. At the moment, bioplastics are the most promising material to head the transition from conventional plastics, those coming from fossil fuels, to a more environmentally friendly solution. However, competing with such a fully consolidated market is not that easy. The main difficulties stem from both the extraordinary development achieved in the field of conventional plastics as well as the relative underdevelopment surrounding bioplastics.

First of all, it may be necessary to clarify what a bioplastic is. It can refer to two different aspects: a polymer obtained from renewable resources (the so-called bio-derived or bio-based); or it can refer to biodegradable polymers, those which can be biologically broken down. Not all the bio-derived polymers are biodegradable, and not all the biodegradable polymers are bio-derived. Needless to say, both options together are preferable.

Polylactic acid (PLA) has become one of the most versatile polymers to substitute conventional plastics in commodity applications. PLA is both bio-derived and biodegradable and its physical and mechanical properties make it suitable to substitute commodity plastics such as polyethylene (PE), polypropylene (PP), polystyrene (PS) and polyethylene terephthalate (PET) in different fields of application. Specifically, a lot of effort is being made to achieve PLA advances in food and beverage packaging, and the substitution of the PET bottle for drinking water is a good example of this.

Nonetheless, several studies have concluded that the environmental advantages of using biopolymers instead of conventional plastics cannot be taken for granted. A detailed analysis of the impact on the environment of both PET bottles and PLA bottles is essential to clarify some important points that must be taken into account.

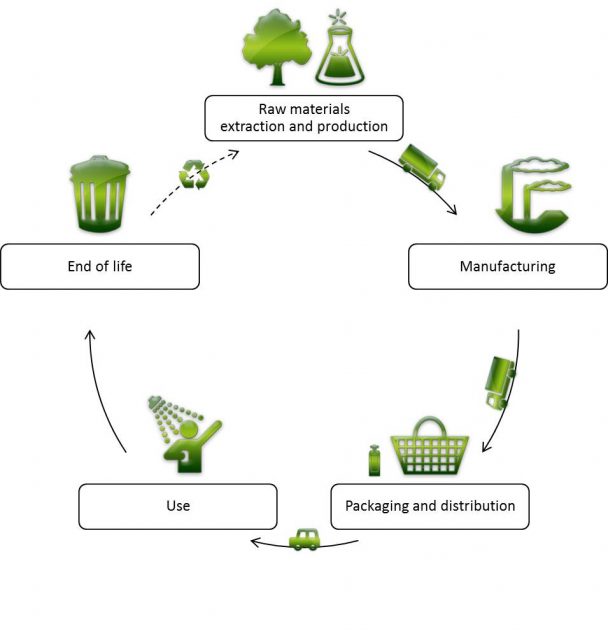

This kind of analysis is provided by the life cycle assessment (LCA), a strong tool to evaluate the environmental impact of a certain product. LCA evaluates the overall interactions between the product and the environment right from the very production of the raw material through the stages of processing, manufacture, distribution, use and final disposal. Throughout its life cycle the inputs and outputs of energy and mass are evaluated.

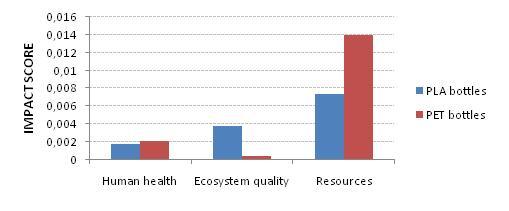

The comparative LCA of PET bottles and PLA bottles, recently studied by Gironi and Piemonte, has come up with some interesting results 2. These results are organized according to the damage caused in three different categories: human health, ecosystem quality and resources. And the parameters measured in each case are the following:

- Human health includes carcinogens, respiratory organics, respiratory inorganics, CO2 emissions, radiation and ozone layer.

- Ecosystem quality includes acidification and eutrophication (sulphates, phosphates, nitrates transferred to soil and water) and land use.

- Resources account for the depletion of non-renewable natural resources (minerals and fossil fuels).

In order to evaluate these parameters, international standards are followed 3, including an international database containing data on energy supply, material supply, chemicals, recycling efficiency and so forth. 4

Firstly, we can consider a “cradle to gate” analysis, that is, the overall interactions from the polymer extraction to the production plant. Surprisingly, here we find that the production of PLA bottles is considerably more harmful to the ecosystem quality than that of PET bottles, mainly due to the use of pesticides, fertilizers, herbicides and consumption of land and water during the crop farming stage of PLA production. On the other hand, the impact on human health is quite similar for both materials and as expected, PET bottle production has a major impact on the depletion of natural resources.

In a more comprehensive approach, the entire life cycle of the product is considered; this is the “cradle to grave” analysis. Now we include the different “end of life” scenarios, which can be incineration, mechanical recycling, landfill and, in the case of PLA, also composting. This analysis shows that the damage caused by PLA crop farming in terms of ecosystem quality and human health can be balanced only if at least an 80% of the PLA is recycled. Otherwise, the production of a PLA bottle will have higher environmental impact than that of a PET bottle. The main problem here is that the plastic sorting systems are still really in the early stage of development.

Ultimately, the important point is that we cannot categorically assure that one material is more environmentally friendly than the other. Depending on the weight assigned to each category (human health, ecosystem quality or resource depletion) we may obtain different results, and also the development of the waste management infrastructure is crucial.

Furthermore, the environmental impact on ecosystem quality and human health is not the only problem that PLA has to face. One of the most important drawbacks of using PLA in food contact applications is its insufficient barrier properties, which means much higher transport rates for water vapor, CO2 and oxygen than most conventional polymers, leading to taste variations and food preservation problems. Moreover, the same processing technologies used for conventional plastics are also frequently used for biopolymers, even if they are not appropriate or even optimal.

Contrarily, the PET bottle market has extensively optimized technology, not only as far as its production is concerned, but also regarding its recycling process. Nowadays an increasing percentage of PET bottles are recycled, with the added advantage that PET can be recycled multiple times and reused in a wide range of applications, considerably reducing emissions and increasing energy recovery.

How should we read these results? Personally, I would say that biopolymers chances of substituting conventional polymers as commodity plastics are very limited unless appropriate technology and optimization of the polymer extraction are adequately developed. Moreover, the extensive use of land required in the PLA crop farming should be regarded as an important issue. In this context, the so-called “cradle to cradle” concept is of utmost importance: the reuse of PLA in a closed loop avoiding the use of land which could be used for food production. But, as is always the case, deeper knowledge and the real support from all the institutions involved in the regulation of waste management infrastructure will be essential.

References

- http://miriamgoldstein.info/research.html ↩

- F. Gironi, V. Piemonte, Environmental Progress & Sustainable Energy, vol. 30, nº 3, p. 459 (2010). DOI: 10.1002/ep.10490 ↩

- ISO 14040:2006, Environmental management – Life cycle assessment – Principles and framework. ISO 14044:2006, Environmental management – Life cycle assessment – Requirements and guidelines. ↩

- http://www.pre-sustainability.com/download/manuals/EI99_Manual.pdf http://www.ecoinvent.org/ ↩

1 comment

Sylvia,

an excellent short review of a complex topic.

And how do we factor in the diversion of food , not just land, to PLA ?

regards

John