Autonomous methods can discover new materials, faster

Scientists have successfully demonstrated that autonomous methods can discover new materials. The artificial intelligence (AI)-driven technique led to the discovery of three new nanostructures, including a first-of-its-kind nanoscale “ladder.”

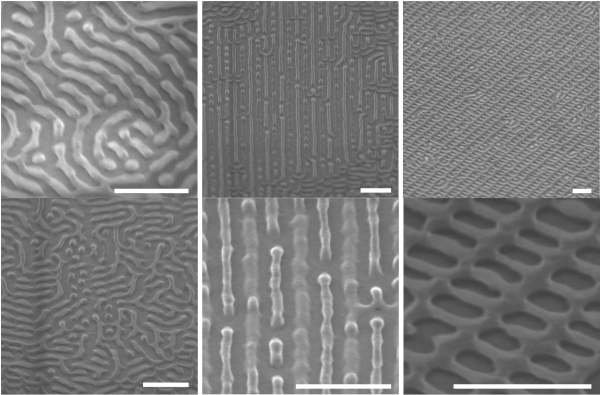

The newly discovered structures were formed by a process called self-assembly, in which a material’s molecules organize themselves into unique patterns. Scientists at Brookhaven’s Center for Functional Nanomaterials (CFN) are experts at directing the self-assembly process, creating templates for materials to form desirable arrangements for applications in microelectronics, catalysis, and more. Their discovery 1 of the nanoscale ladder and other new structures further widens the scope of self-assembly’s applications.

“Self-assembly can be used as a technique for nanopatterning, which is a driver for advances in microelectronics and computer hardware,” said CFN scientist and co-author Gregory Doerk. “These technologies are always pushing for higher resolution using smaller nanopatterns. You can get really small and tightly controlled features from self-assembling materials, but they do not necessarily obey the kind of rules that we lay out for circuits, for example. By directing self-assembly using a template, we can form patterns that are more useful.”

The scientists aim to build a library of self-assembled nanopattern types to broaden their applications. In previous studies, they demonstrated that new types of patterns are made possible by blending two self-assembling materials together.

“The fact that we can now create a ladder structure, which no one has ever dreamed of before, is amazing,” said CFN group leader and co-author Kevin Yager. “Traditional self-assembly can only form relatively simple structures like cylinders, sheets, and spheres. But by blending two materials together and using just the right chemical grating, we’ve found that entirely new structures are possible.”

Blending self-assembling materials together has enabled researchers to uncover unique structures, but it has also created new challenges. With many more parameters to control in the self-assembly process, finding the right combination of parameters to create new and useful structures is a battle against time. To accelerate their research, CFN scientists leveraged a new AI capability: autonomous experimentation.

An AI framework has been developed that can autonomously define and perform all the steps of an experiment. An algorithm called gpCAM drives the framework’s autonomous decision-making. The latest research is the team’s first successful demonstration of the algorithm’s ability to discover new materials.

To accelerate materials discovery using their new algorithm, the team first developed a complex sample with a spectrum of properties for analysis. “An old school way of doing material science is to synthesize a sample, measure it, learn from it, and then go back and make a different sample and keep iterating that process,” Yager said. “Instead, we made a sample that has a gradient of every parameter we’re interested in. That single sample is thus a vast collection of many distinct material structures.”

Then, the team brought the sample to National Synchrotron Light Source II (NSLS-II), which generates ultrabright x-ray beams for studying the structure of materials “One of the beamline’s strengths is its ability to focus the x-ray beam on the sample down to microns,” said NSLS-II scientist and co-author Masa Fukuto. “By analyzing how these microbeam x-rays get scattered by the material, we learn about the material’s local structure at the illuminated spot. Measurements at many different spots can then reveal how the local structure varies across the gradient sample. In this work, we let the AI algorithm pick, on the fly, which spot to measure next to maximize the value of each measurement.”

As the sample was measured at the beamline, the algorithm, without human intervention, created a model of the material’s numerous and diverse set of structures. The model updated itself with each subsequent x-ray measurement, making every measurement more insightful and accurate.

In a matter of hours, the algorithm had identified three key areas in the complex sample for the CFN researchers to study more closely. They used electron microscopy to image those key areas in exquisite detail, uncovering the rails and rungs of a nanoscale ladder, among other novel features.

From start to finish, the experiment ran about six hours. The researchers estimate they would have needed about a month to make this discovery using traditional methods.

“Autonomous methods can tremendously accelerate discovery,” Yager said. “It’s essentially ‘tightening’ the usual discovery loop of science, so that we cycle between hypotheses and measurements more quickly. Beyond just speed, however, autonomous methods increase the scope of what we can study, meaning we can tackle more challenging science problems.”

References

- G.S. Doerk et al (2023) Autonomous discovery of emergent morphologies in directed self-assembly of block copolymer blends Science Advances doi: 10.1126/sciadv.add3687 ↩