When gnomes sit on rails

Unlike road vehicles, all rail vehicles run through exactly the same piece of track and they cannot drift away to avoid a bad quality rail. Moreover, the contact patch between wheel and rail is a steel-to-steel contact with a small area and huge loads, so the stress the material is subject to is extremely high. Luckily, decades of research on improved quality materials have reduced the catastrophic defects of rails up to virtually removing them from our daily lives.

Still, different damage modes occur in rails, even if not catastrophic. The most recurring one is the appearance of fatigue cracks in the contact thread. For those not familiar with the mechanical properties of materials, fatigue failure is generated by stressing the material with cycles of high and low forces, and it is usually much more effective than brute force if you want to break a teaspoon, for example. In the case of rail vehicles, constantly rolling over the same spot generates a fatigue cycle along the rail, and when a crack finally appears we get the damage known as Rolling Contact Fatigue (RCF). There are different RCF modes, most of them having in common the appearance and growth of cracks until a small piece of rail of some millimeters (sometimes called “shell”) is detached. This creates a nonlinearity on the rail that generates higher dynamic forces and decreases comfort, but is not critical at all. There are, however, dangerous RCF modes that might eventually crack the rail in two pieces if maintenance is not properly performed.

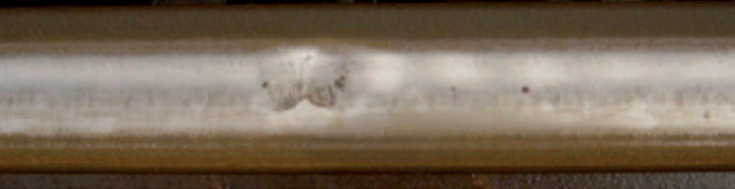

In the late 1960s a new type of damage started to appear when some British lines were upgraded, which was christened as Squat. As Grassie 1 states, it is “one of the more prosaic contributions of engineers to etymology”. ‘Squat’ means to crouch and sit over your ankles. The defect “looks as though a very heavy gnome has sat or squatted on the rail producing an indentation shape with two lobes of similar size”. Its characteristic shape can be clearly seen in Figure 1.

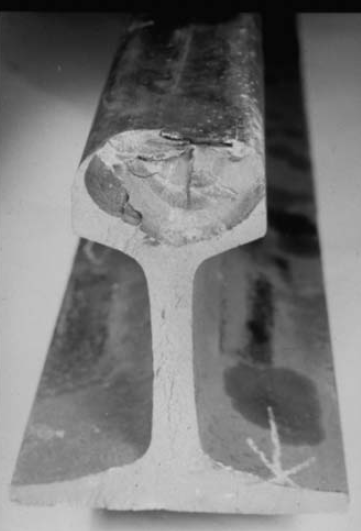

Squats are surface generated RCF modes, usually starting with a heavy sheared and plastically deformed surface, initiated by a small piece of debris attached to the wheel. Then, the fatigue cycles develop the crack inside the rail head, typically at around 5mm depth (Figure 2), where residual stresses are highest during the load cycle. They develop in the direction of the running vehicle, both forward and backward, and the weakening of the rail in the crack area is what generates the characteristic double-lobbed shape on the outer surface of the rail. 100 Million Gross Tones (MGT) are needed in order to start developing a crack, which might take several years after new rails are deployed.

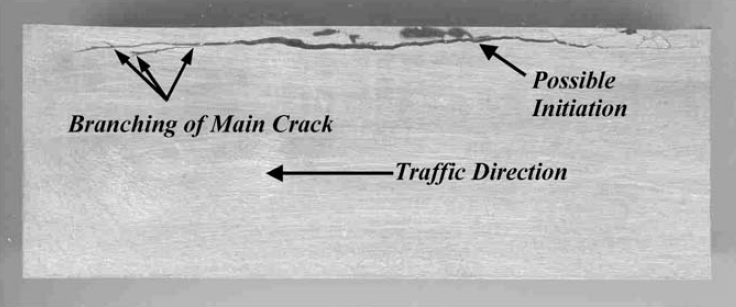

These cracks have another peculiarity. It was observed that i) the crack following the direction of the run was always larger than the one going backwards, and ii) cracks did not develop in tunnels. These two characteristics are because atmospheric water has a critical effect in their development. Water or melted snow is trapped in the cracks. Then, when next wheelset runs over it, the water in the back-crack is expelled, while the water in the forth-crack cannot escape, as the wheel is obstructing the only exit and compressing it at the same time. The high pressures generated on the almost incompressible fluid break the softest parts around the crack, the inter-granular ferrite, making the crack grow. Also, if temperatures drop below zero, the increase of volume of water when becoming ice increases the damage even more. If neither the crack or the load are removed, it will eventually branch in a vertical crack that will tear apart the rail (Figure 3).

The actual strategy to avoid this kind of failure is to preventively grind the rails in a regular basis, so surface damage is removed: cracks seldom initiate and, when they do, they never have time to develop into squats or critical rail failures.

For some years, research on squats has been reduced, as it was considered that the effect and its solution were completely understood. However, some squat-like defects have been appearing recently in conditions were squats are not usually found, i.e. urban railways with very low MGT. Even the ultrasound devices used for in-rail crack detection classify them as squats. But after careful research, Grassie et al 2 have concluded that this is a different type of defect, which has been baptized as Stud.

Looking at the microscopic material properties of these cracks, there are no signs of oxidation inside the crack, so water does not take active part on its development. Also, cracks do not follow the soft inter-granular ferrite, but can be found braking through pearlitic grains. Even the authors are reluctant to give any explanations to this phenomenon. Their hypothesis is that the crack might be initiated by some martensitic steel structures found in the surface of the studs. Martensite is generated when heating the steel to temperatures over 727°C, which might happen if a sudden friction coefficient increase appears in one of the wheels while the whole wheelset is sliding; and then cooling it very quickly, which is very plausible due to the high thermal inertia of the rails, that will dissipate the heat very quickly. They still insist that the mechanism by which the crack is propagated is unclear. As a good point, studs don´t seem to have a critical failure mode: cracks don’t develop vertical branches that could break the whole rail. They appear early, they develop in an unknown manner, but at least they are not critical for passenger safety.

Because of the recently discovered studs, there is a renewed interest on RCF damage in railway literature, trying to understand the underlying mechanisms of initiation and propagation. But at the end of the day this is the one detail that stays: they named a very dangerous RCF damage type after the buttocks of a gnome. And they say that English people have no sense of humour.

References

- S L Grassie, ‘Squats and squat-type defects in rails: the understanding to date’, Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit 2012, v226, pp. 235-242 ↩

- S L Grassie, D I Fletcher, E A Gallardo Hernandez and P Summers, ‘Studs: a squat-type defect in rails’, Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit 2012, v226, pp. 243-256 ↩