Moving pyramid stones on sand

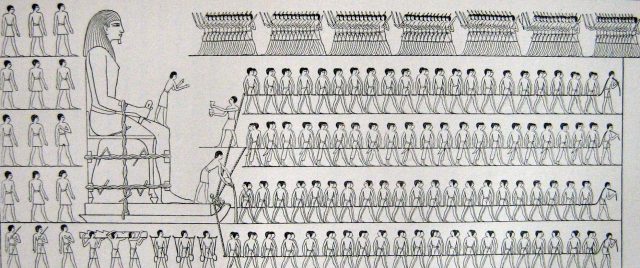

Of all the seven wonders of ancient times, only the pyramids of Egypt remain on their feet. The technical means Egyptians had that many years ago for building these huge structures were extremely limited, and that is the main reason for them being so fascinating: they could build them despite the huge technical difficulties they had to fight against. The pyramids, as for the Moai statues at Easter Island, didn’t have their materials available in-site where they were built, but had to transport huge blocks of limestone from nearby quarries. Moreover, the granite used in the Pharaoh’s chamber was imported from Aswan, using the Nile River for most of the trip, but eventually moving them through sand. Now, dragging huge stone blocks on sand is not the most efficient way to transport them, and that is why there have been several hypotheses on how they moved them. However, the general consensus is that they dragged the stones on wooden sledges.

When dragging any item through the ground you have to overcome the maximum friction force that the contact patch can exert. Friction force can be modelled in a simplified way with the so called Coulomb model, where the maximum tangential force value is equal to the normal force (this is, the weight of the pulled element) and the friction coefficient between the two surfaces. If the element is heavy, such as pyramid blocks, and the contact is not smooth, such as limestone against sand, then the needed pulling force is huge. But friction is tricky phenomena, and so are sand physics; so you can picture their combination. And now, a recent publication in Physical Review Letters has found that adding water to the sand reduces the friction coefficient 1, contradicting previous works that stated the opposite. Adding “multiphase mechanics” to the former two topics makes it even trickier, as you can guess, so let’s take it slowly.

First of all, sand is a granular solid, which means that each of its micro-scale grains is very stiff, but its macro-scale behaviour of hundreds of thousands of grains is more similar to a flexible body. When you try to drag a solid on a flexible body, friction is no longer a purely tangential behaviour, but starts to affect the vertical forces because of the deformation of the contact patch. This is why friction forces are separated in two categories when flexible bodies are involved, as we saw in a previous article: dry friction, which accounts for the energy loss when tangentially sliding parallel surfaces; and ploughing friction, which accounts for the energy required to deform an elasto-plastic surface so the tangential sliding can continue. For a “flowable ground” such as sand, the deformation of the contact patch in the front of the sledge will make the whole system “sink” slightly in the sand, which partly accounts for the ploughing friction.

The best way to reduce the plough is to increase the stiffness of the flexible solid, while the best technique for reducing dry friction is using some lubricant fluid: here is where water comes in. According to the authors, adding water to the sand reduces the friction coefficient and increases the stiffness of the mixture, but (and here is the whole point) only for a specific amount of water.

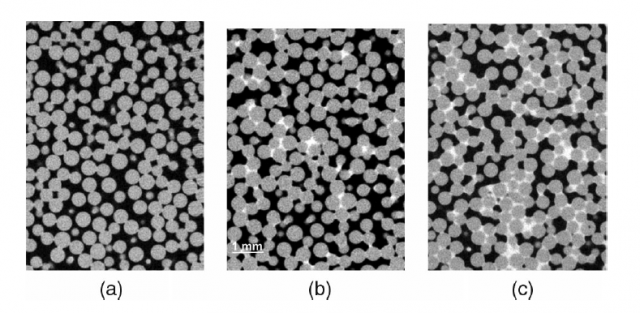

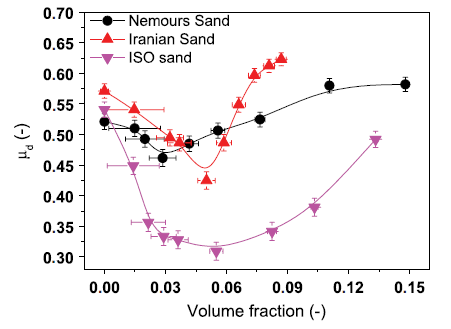

When a small amount of water is poured on the sand, grains are coupled with water bridges, heavily increasing the macro-scale stiffness (Figure 1). When more water is poured, this bridges start to merge, decreasing the stiffness back as the ratio surface tension/fluid volume decreases. The optimal stiffness values are obtained within 3% to 4% water/sand ratio (Figure 2). Regarding the friction coefficient, water usually reduces it acting as a lubricant, but when a granular solid is involved, the movement between the grains has to break these water bonds, increasing the energy spent at the tangential displacement. In this case, the optimal amount of water is close to 5%, and the peak is very sharp: for slightly more or less water volume fraction the friction coefficient rapidly increases. The funny thing is that, at some point around 7% water volume fraction, friction coefficient of wet sand is higher than that of dry sand. Too much water is even worse than just dry sand.

So you can’t really just pour water, you need to be very precise. If Egyptians really used this technique for reducing the drag force of the blocks, they probably went through many trial and errors before they got the right amount of water for their sand. But that’s a good point, for their sand. Because sand is not the same all around the world, and these analyses were carried out with Iranian sand. Checking upon different types of sands, it is noticeable the difference in grain size distribution between the Iranian or the Nemours sand (with many grains around 200 m) and the ISO normalized or the Egyptian sand, much more polydisperse than the former two, with more evenly distributed grain sizes. For the ISO sand, the decrease of friction coefficient when damping it is much more pronounced, and the effect lasts for a wider volume fraction of water (Figure 3). The minimum friction value is at ca. 5.5% water, but the reduction is good enough between 3% and 8%. And you have to wet it really badly in order to get friction coefficients higher than the one of dry sand, so the precision needed for the right amount of watering is not so high.

The main conclusion I get from this paper is that the analysis of sand drag is very tricky, as it has huge variations depending on grain distribution or humidity. And that Egyptians were both pretty smart to overcome the technical difficulties of building such impressive monuments, and very lucky that they got just the right sand.

References

- Fall A., M. Pakpour, N. Lenoir, N. Shahidzadeh, J. Fiscina, C. Wagner & D. Bonn (2014). Sliding Friction on Wet and Dry Sand, Physical Review Letters, 112 (17) DOI: http://dx.doi.org/10.1103/physrevlett.112.175502 ↩

5 comments

[…] zuten egiptoarrek, harean harrizko bloke erraldoiak garraiatzeko? Carlos Casanuevak azaltzen digu Moving pyramid stones on sand […]

Excelent post, Carlos. However, nobody has ever explained or figured out how Egyptians lifted those heavy stones. Or did they already knew the pulley?

I am not an expert in egyptology, so this is just a guess from the top of my head: they rolled them on their corner on top of the sledges. Rolling is much easier than dragging (less energy cost), doesn’t need any special structure and the height they need to overcome is not that big, so it might just be enough.

Or maybe you mean to the top of the pyramid? I think that’s rather settled, they used auxiliary wooden and sand structures to pull them “uphill” to their proper level. But again, I’m no expert…

[…] Las cuales también se han invocado para explicar otras megaconstrucciones, como por ejemplo las pirámides de Guiza. Por ello es interesante encontrar un nuevo artículo, recién publicado en Physical Review Letters, en el cual se muestra experimentalmente que añadir […]