Bamboo bikes are better for your buttocks

Bicycles are usually regarded as the most sustainable mean of transport for urban environments. Now, when talking about sustainability, there are usually two different discussions: on the one hand, there is energy sustainability, as the fossil fuels won’t last forever and their secondary products are quite unhealthy. Bikes, being powered by people, fully comply with this criteria; on the other hand there is manufacturing sustainability, where the materials used for different products, even if not consumed during the process as in the case of fossil fuels, are limited and must be used with care in order not to deplete them. Also, the processing of these materials might cost energy and generate residues, which should also be minimized for the sake of sustainability. For example, aluminium bikes are a lightweight option that uses one of the most resource-demanding materials in the manufacturing world.

What if we could substitute the materials in the frame with a material that we can cultivate? This is not something new or revolutionary; actually the first bikes were wooden. But still, wood has to be processed so we get proper shapes. There is a great alternative: bamboo canes. Tubular wooden logs with great structural behaviour which need little more than cutting them to the right length seem the perfect choice for this task. They are extensively used as a structural material in most Asian countries, and they are one of the fastest growing plants on earth. Well, still old news; it was patented in 1894 in England. It didn’t have much success then, but due to its reduced cost it is now a booming option in poor countries, especially in Africa (The Bamboo Bike Project). It seems quite trendy in the developed world too, with bike selling companies adding them as a sustainable option to their catalogues.

In a previous article we saw that the bike is self-stable at certain speeds, and how you could increase its stability by acting upon different parameters of the model. However, this model was implemented with a rigid frame. Being bamboo canes much more flexible than metal frames, this simplification should be disregarded and consider the influence of its structural flexibility. For instance, in order to analyse how this flexibility affects ride comfort, researchers from Oxford Brookes University have developed a methodology that allows comparing bamboo and aluminium frames 1.

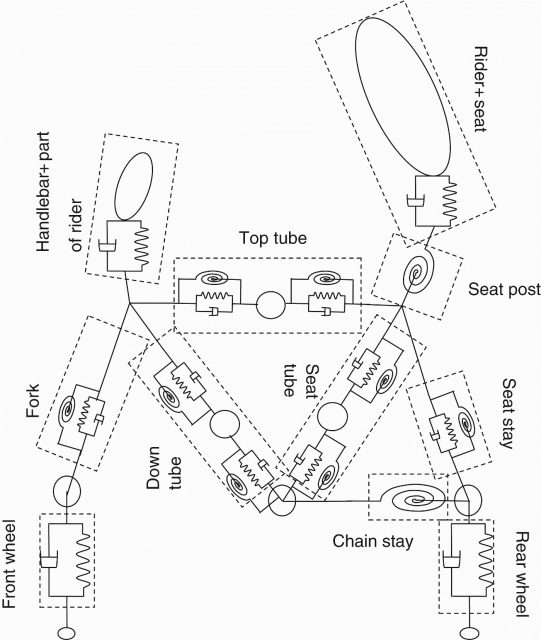

It is actually quite difficult to quantify comfort in bicycles. The dynamic response of rider and bike depends on the combined bicycle-rider dynamics and track geometry. Vibration modes of bicycles are a function of a diversity of components: frame, wheels, tyres, even the rider influences the dynamics of the whole system. Actually, the variety of tyres is the most difficult part to analyse, as there is huge variation in stiffness and damping characteristics between different rubber elements. You could even add bike suspensions such as the ones used in high performance mountain bikes, complicating even further its dynamic modelling. The authors built a lumped mass model that accounts for most of these parameters, and built their own bamboo bike according to quality standards in order to validate this theoretical model with experimental measurements.

The methodology to measure discomfort was based on the studies performed in ground vehicles. The relationship between road topology and rider vibration was theoretically calculated and validated with experiments in the form of frequency response functions. However, there is a complex relationship between the accelerations acting upon a person and his perceived ones, this is, his level of comfort. For instance, for the same level of vertical acceleration, sitting is less comfortable than standing; different frequencies with the same amplitude are sensed in a different way; even the direction for the vibration has an influence, as angular vibrations lead to higher discomfort for lower frequencies; it’s all about human perception. Gathering all the information available in the literature for seated transmission and hand transmission, and using the ISO 2631 standard for Evaluation of Human Exposure to Whole-Body Vibration 2 they developed a weighting methodology that accounts for the perception of vibration while sitting in a bike, obtaining discomfort values that could be quantified and measured.

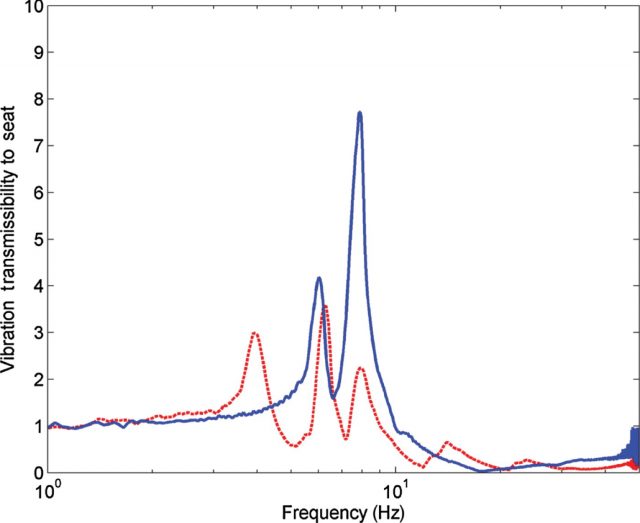

Looking at the transfer functions such as Figure 2, the difference in acceleration transmission between an aluminium frame and a bamboo frame are evident. First, flexible modes for the bamboo frame have lower frequency due to its higher flexibility; on the other hand, bamboo has much higher structural damping than aluminium, around ten times higher, so the amplitude of these accelerations is much lower. The difference for front wheel – handlebar transference is not so evident, as the vibration transmission is quite straightforward avoiding the whole frame, where the structural differences are highest.

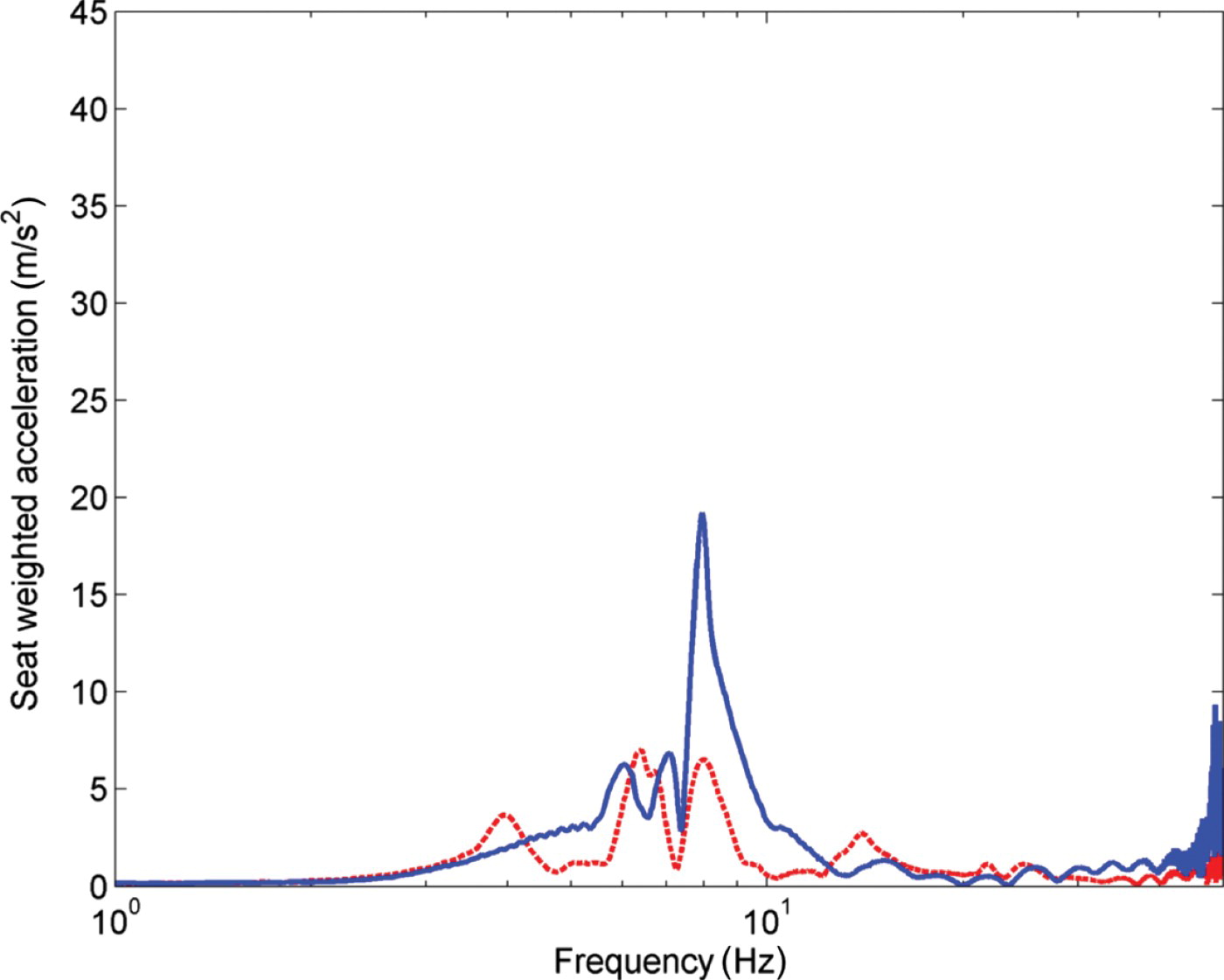

But as previously mentioned transfer function is not directly translated into discomfort. Still, when comparing the weighted accelerations the results are very similar, cf. Figure 3. The vibration over the bike seat is lower for bamboo frames, but there is not much difference in amplitude for handlebar vibrations. However, handlebar transmission has a significant difference in frequency, as the peak for the bamboo frame is around 15Hz, while between 25Hz and 35Hz is the aluminium frame which worsens ride quality.

So the conclusion is that, for a general purpose bike, it is better to use bamboo for the frames rather than aluminium. It is cheaper and has less environmental impact. Also, considering only ride comfort, bamboo frames perform better, but not for handlebar vibrations. You will only feel the improvement through your buttocks, which is quite a sensitive part anyway. Will the structural flexibility affect riding stability and lateral dynamics? Someone should study it; we don’t want these bikes to be less safe for the riders.

References

- Thite A.N., Gerguri S., Coleman F., Doody M. & Fisher N. (2013). Development of an experimental methodology to evaluate the influence of a bamboo frame on the bicycle ride comfort, Vehicle System Dynamics, 51 (9) 1287-1304. DOI: 10.1080/00423114.2013.797591 ↩

- International Organisation of Standardisation, ISO 2631-1, Mechanical Vibration and Shock – Evaluation of Human Exposure to Whole-Body Vibration, Geneva, 1997. ↩

3 comments

[…] aluminiozkoa baino. Hori ba, soilik ipurdian nabarituko duzu onura. Carlos Casanuevak azaltzen digu Bamboo bikes are better for your buttocks. Haren testua, Science Seeker editoreen asteko hautaketan […]

[…] bambú que de aluminio. Eso sí, notarás el beneficio sólo en las posaderas. Carlos Casanueva en Bamboo bikes are better for your buttocks. Incidentalmente, este texto está en la selección de los editores de esta semana en Science […]

[…] Este artículo está basado en el publicado originalmente en inglés en Mapping Ignorance: Bamboo bikes are better for your buttocks […]