What lignin can do in cellulose nanofibre hydrogels

What lignin can do in cellulose nanofibre hydrogels

Hydrogels are fascinating materials that can absorb and retain large amounts of water, making them useful in various fields such as medicine, environmental science, and engineering. A recent study has explored 1 a new type of hydrogels made from cellulose nanofibres (CNFs) and lignocellulose nanofibres (LCNFs), aiming to enhance their strength and water-absorbing capabilities.

Cellulose and lignocellulose nanofibres

Cellulose is a natural polymer found abundantly in plant cell walls. When broken down into tiny fibres, known as cellulose nanofibres (CNFs), they exhibit impressive strength and flexibility. Lignocellulose nanofibres (LCNFs) are similar but contain lignin, a complex organic polymer that provides rigidity to plants. Incorporating lignin into these nanofibres can influence the properties of the resulting materials.

In the study, researchers extracted CNFs and LCNFs from eucalyptus pulp using a process called homogenization. They then prepared water-based suspensions with varying concentrations of these nanofibres. To form the hydrogels, they employed a freeze–thaw method, which involves freezing the suspension and then allowing it to thaw. This process encourages the formation of physical cross-links between the nanofibres, resulting in a three-dimensional network capable of holding water.

Hydrogels with different properties

The team examined how different compositions of CNFs and LCNFs affected the hydrogels’ characteristics. They found that increasing the concentration of nanofibres led to stiffer hydrogels. Notably, hydrogels containing LCNFs demonstrated superior mechanical properties compared to those with only CNFs. This suggests that the presence of lignin contributes to a more robust structure.

On the other hand, hydrogels with LCNFs showed a remarkable ability to absorb water, swelling up to 8750% of their original weight, while those with only CNFs reached about 5500%. The lignin in LCNFs appears to enhance the hydrogel’s capacity to take in water.

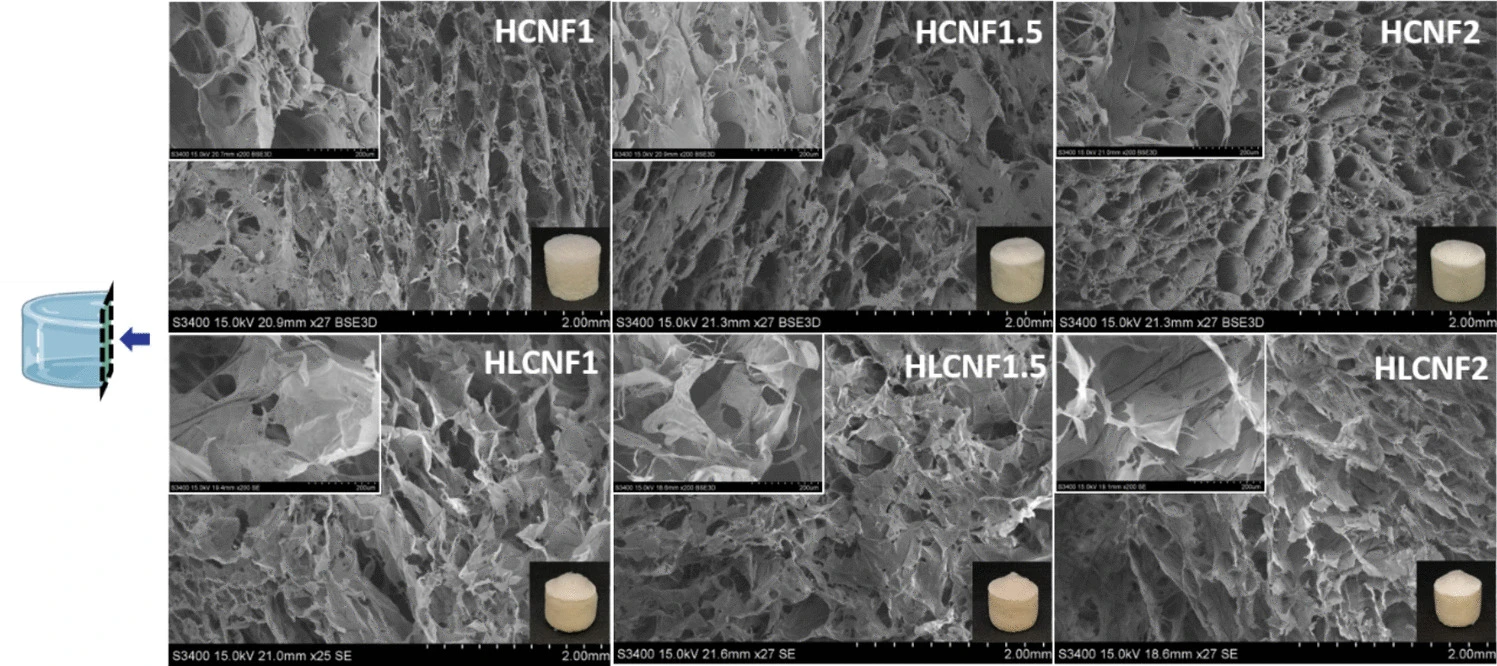

Finally, upon examining the internal structure, researchers observed a honeycomb-like pattern in the hydrogels. Those made with LCNFs had less smooth walls, which might influence their mechanical and absorption properties.

The role of lignin

Lignin plays a crucial role in determining the behaviour of these hydrogels. Its presence affects how the nanofibres cross-link during the freeze–thaw process, leading to changes in both strength and water absorption. Density functional theory (DFT) calculations supported these findings, showing that water molecules facilitate cross-linking between cellulose chains, and lignin modifies this interaction.

The enhanced properties of these LCNF-based hydrogels open up new possibilities. By understanding and manipulating the role of lignin, scientists can design materials tailored for specific applications, contributing to advancements in various industries. Some examples are: Their high water absorption and strength make them suitable for wound dressings, providing a moist environment that can promote healing; these hydrogels could be used in water purification systems, acting as efficient absorbents to remove contaminants; or, incorporating these hydrogels into soil could help retain moisture, benefiting crop growth in arid regions.

Author: César Tomé López is a science writer and the editor of Mapping Ignorance

Disclaimer: Parts of this article may have been copied verbatim or almost verbatim from the referenced research paper/s.

References

- Baraka, F., Morales, A., Velazco-Cabral, I., Rivilla, I., Labidi, J. (2025) Physically cross-linked cellulose nanofiber (LCNF/CNF) hydrogels: impact of the composition on mechanical and swelling properties. Adv Compos Hybrid Mater doi: 10.1007/s42114-025-01218-z ↩